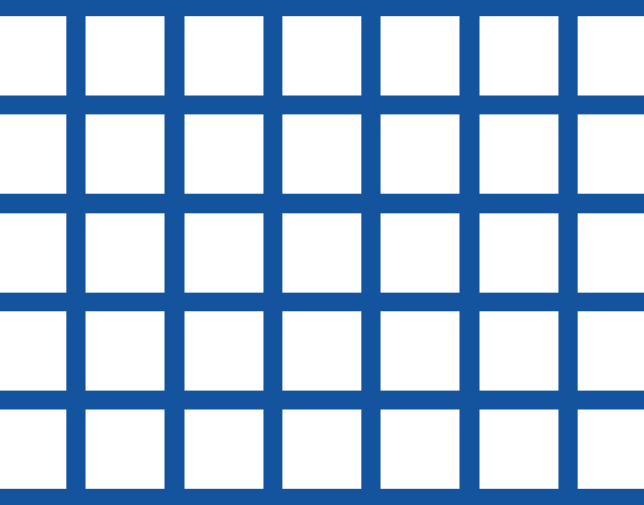

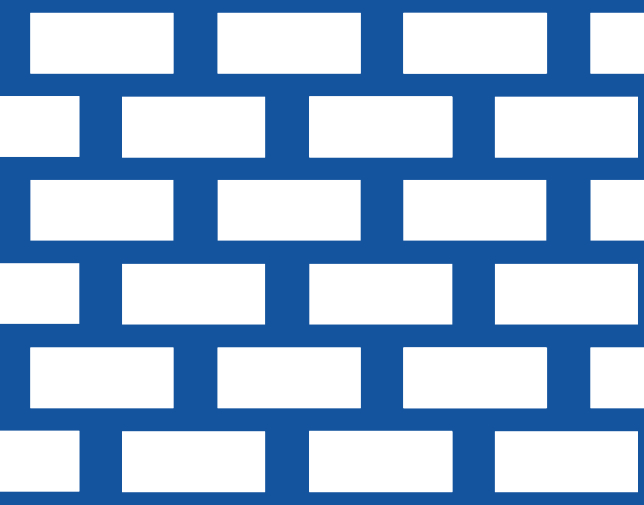

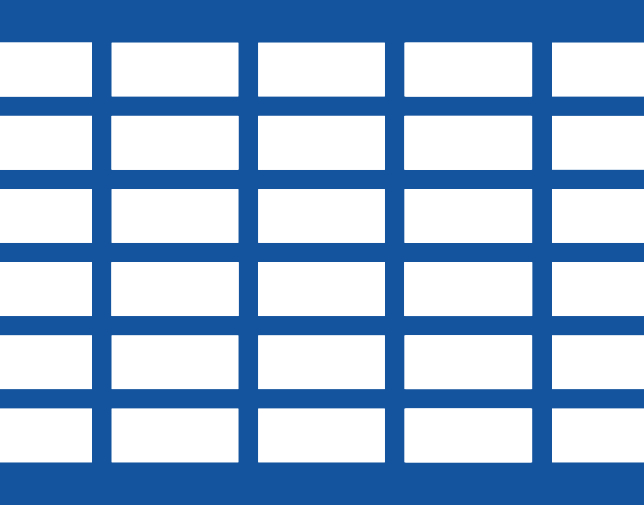

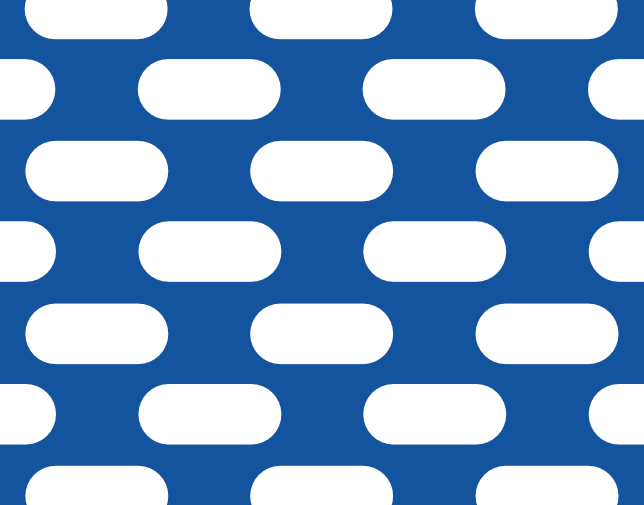

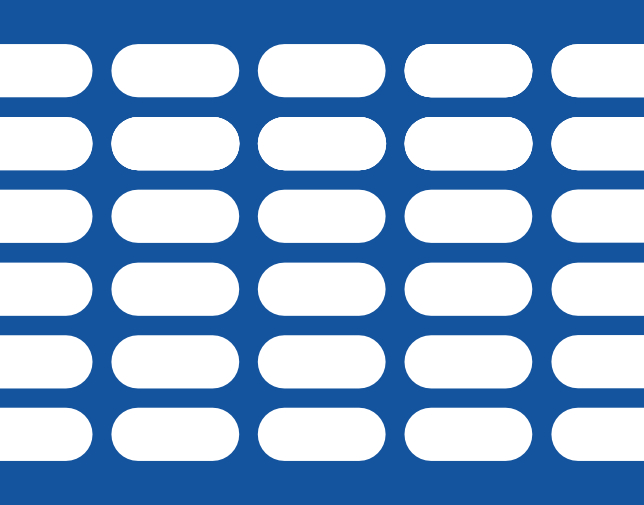

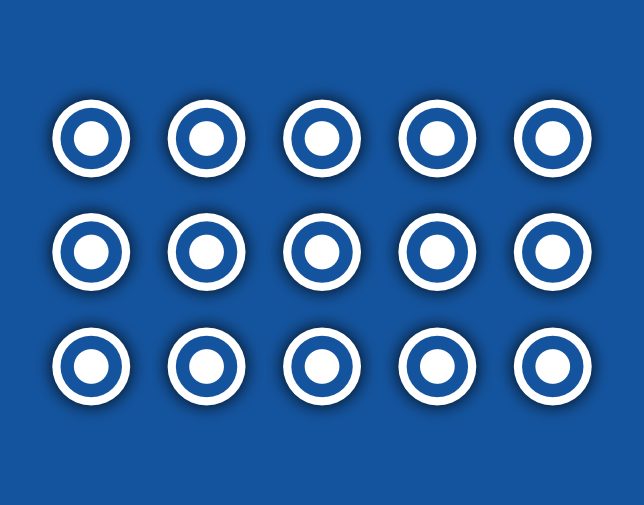

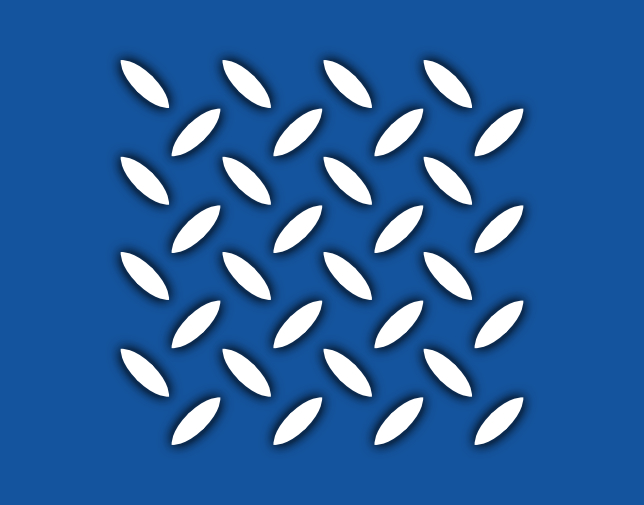

HOLE SHAPES & PATTERNS

We can punch holes of practically any shape but the common shapes are shown above and include: round, square, diamond, rectangular with round or square corners.

Similarly we can punch holes over a wide range of patterns, from plain square or rectangular, angled, offset longitudinally or laterally.

We have a huge range of tooling and expertise in CNC punching and above are just a few examples. Our capability to create perforated components is unlimited and includes all shapes and sizes with holes from 2mm to 100mm diameter.

Basic information on perforation shapes and patterns

The standard and most popular perforation patterns can be identified by ascertaining some or all of the following information:

- The hole size and shape

- The hole pattern / pitch (the distance between hole centres)

- The course of the pattern / pitch in relation to the edge of the sheet

- The solid section of material between holes (bridge)

- The margin(s) around the edge of the sheet

Basic perforation terminology

- Length (of plate or sheet) – this is the longer dimension of the two

- Width/Height (of plate or sheet) – this is the shorter dimension of the two

- Margin/Border – this is the un-perforated/plain area around the edge of the plate or sheet

- Pitch – this measurement is taken from the centre of one hole to the centre of the neighbouring hole

- Bridge – this is the measurement of the solid section of material between the holes