Additional Services

Metal Rolling

C&S Fabrications have the ability to roll sheets and plate to a radius or full circumference where required. C&S have the ability to roll material up to 3000 mm in length with a maximum thickness of 10 mm. Rolling is a vital process required when producing industrial screens for the recycling, mining and agricultural industries, but it is also used for a variety of architectural purposes on perforated panels and sheeting.

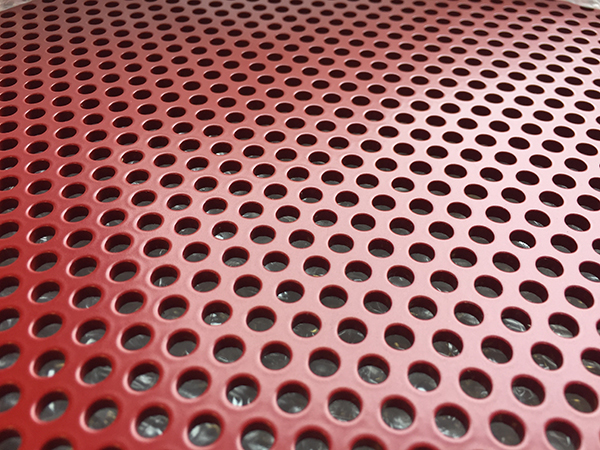

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a “skin”. C&S Fabrications are able to offer a powder coating service to complement fabrication, perforation and laser cutting.

Galvanising & Zinc Plating

Galvanising can protect metal is a number of ways. Firstly, it creates a protective coating that shields the metal from the surrounding environment. The layer of zinc prevents water and moisture and other elements in the air from corroding the steel underneath. C&S Fabrications are able to offer galvanising and zinc plating to complement fabrication, perforation and laser cutting.

Machining

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. The processes that have this common theme, controlled material removal, are today collectively known as subtractive manufacturing, in distinction from processes of controlled material addition, which are known as additive manufacturing. C&S Fabrications are able to offer machining services to complement fabrication, perforation and laser cutting.